How to Calculate the Stiffness of a Rectangular Spring

I. Introduction to Rectangular Springs

Rectangular springs are helical springs with rectangular or square cross-sections. They are commonly used in space-constrained or high-load scenarios, such as die springs, automotive clutches, and stamping equipment. Compared to round wire springs, rectangular springs have higher energy storage density and stiffness per unit volume, making them suitable for high-frequency, high-load applications.II. Stiffness Calculation Formula for Rectangular Springs

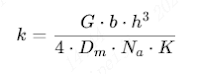

The stiffness (k) of a rectangular-section spring is defined as the force required per unit deformation. The calculation is more complex than for round wires and considers material, geometry, and spring type (compression/torsion/tension).General formula for compression springs:

-

k = spring stiffness (N/mm)

-

G = shear modulus (MPa), ~79,300 MPa for standard spring steel

-

b = width of rectangular cross-section (mm)

-

h = height of cross-section (mm)

-

Dₘ = mean coil diameter = inner diameter + thickness (mm)

-

Nₐ = number of active coils (excluding support coils)

-

K = correction factor for non-circular sections, based on b/h ratio

III. Key Factors Affecting Rectangular Spring Stiffness

-

Material Shear Modulus

Materials with higher shear modulus (e.g., chromium-silicon steel, music wire) offer greater stiffness. -

Cross-section Ratio (b:h)

-

Height (h) affects stiffness cubically—most impactful.

-

Width (b) affects stiffness linearly.

-

Number of Active Coils

More coils = lower stiffness; fewer coils = higher stiffness, but reduced stroke. -

Mean Diameter (Dₘ)

Larger Dₘ = lower stiffness; smaller Dₘ = higher stiffness but higher fatigue risk.

IV. Design and Selection Recommendations

-

For high stiffness: Use springs with greater cross-section height, fewer coils, and smaller mean diameter.

-

For high-frequency die use: Select high-stiffness rectangular die springs (e.g., ISO 10243 standard).

-

For limited space: Rectangular springs save more space than equivalent round wire springs.

-

For durability: Balance stiffness and fatigue life; avoid excessive compression.

-

Consider temperature effects: High temperatures lower the modulus, reducing stiffness.

Comments

Post a Comment